摘要

冲压制品已在工业,农业,国防和日常生活中的方面得到广泛应用,特别是在机械业中则为突出。机械产品的外壳大部分是冲压制品,产品性能的提高要求高素质的冲压模具和冲压性能,成型工艺和制品的设计。

冲压制品的成型方法很多。其主要用于是冲孔,落料,弯曲,拉伸等。而冲压模,约占成型总数的60%以上。当然如利用电气控制,可实现半自动化或自动化作业。

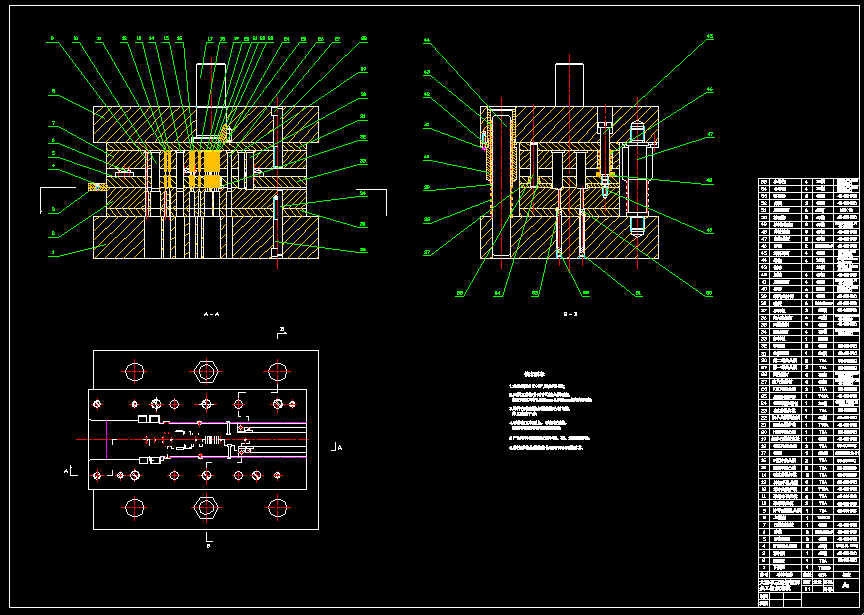

冷冲冲裁模主要用于金属制品的成型,它是冲压制品生产中十分重要的工艺装置。冲压模的基本组成是:上下模座、下模垫板、下模固定板、凹模镶块、抬料钉、导料板、卸料板,导柱导套、卸料板弹钉、卸料板等。

冲裁模成型的广泛适用,正是我这个设计的根本出发点。

关键词:冲孔、落料

Abstract

Stamping products has been extensively applied in the industry, agriculture, national defense and in the daily lives of area, especially in the machinery industry. Mechanical products is the most pressing housing products, and the improvement of product performance requires of high-quality performance stamping molds ,stamping,process and product design.

There are many ways of molding products of stamping. Piercing is mainly used for blanking, bending, stretching, etc. And Stamping molds almost form more than 60 percent of the total number. For example ,Electrical Control can be realized as semi-automatic or automatic operation.

Cold-metal stamping die mainly used for the molding products, and it is very important in the production of stamping technology devices. The basic component of stamping molds is block model from top to bottom, mould plate, fixed-plate of mould plate, die inserts, raising nails, I. plate

, plate unloading I. Introduction sets column, unloading bombs nail plate, plate Discharge and so on.

The widely application of blanking moulding is exactly the basic perpose of my design.

Key wards:Piercing、Blanking

目录

一.零件的工艺性分析… 1

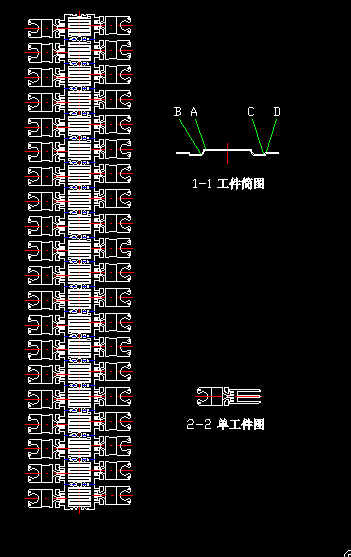

二.排样图设计………………………………………………… 1

三.工艺与设计计算…………………………………………………… 2

冲裁力……………………………………………………………… 2

2.弯曲力……………………………………………………………… 2

3.计算压力中心 3

4.计算各主要零件的尺寸 3

(1).凹模厚度 3

(2).凸模固定板的厚度 3

(3).垫板的采用与厚度 3

(4).卸料零件的计算 4

(5).计算凸凹模工作部分尺寸 4

(6). 冲裁间隙 8

四.模具总体设计 8

五.模具主要零部件的设计 8

1.模架 9

2.冲裁凸、凹模 10

3. 卸料板 11

4.导尺的设计 11

5. 定位装置 11

6. 限位装置 11

六.凹﹑凸模的线切割加工工艺 12

1.凹模的准备工序 12

2.凸模的准备工序 13

七.模具制造装配要点 13

八.压力机的选择 13

九.参考资料目录 15

十.结束语 16