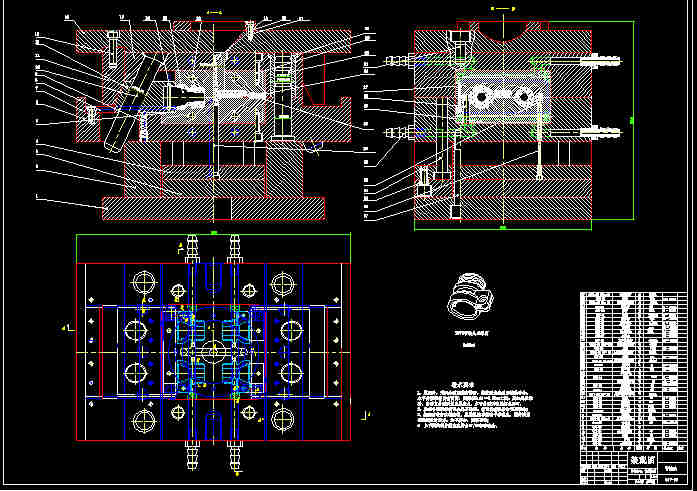

管接头注射模具设计

摘要 :在现代工业中,模具工业已成为制造业的基础,这一观点随着全球制造业向我国转移的过程中以被越来越多的有识之士所意识到。而在模具行业中塑料模又是其重中之重,种模具占模具行业总份额的50%以上,我国的塑料成型模具设计,制作技术比较晚,整体水平还比较低。目前单型腔、简单型腔的模具达70%以上,仍占主导地位。本论文介绍了管接头的注射模设计过程。从型腔数量和布局的确定、注射机选择、浇注系统设计、模板及其标准件的选用、脱模及抽芯机构的设计、成型部件的设计等一一进行了详细的介绍。塑件有侧孔,需要设计侧向抽芯机构,增加了模具的复杂程度。

关键词:注射模;侧向抽芯;管接头

The Design of Union Injecting Molding

Abstract In the modern industry, the die industry has become the foundation of the manufacturing industry, this standpoint was along with the process that world manufacturing industry transfer to our country, which was been aware of by the private who more and more know. But in die profession plastics mold was heavy its heavy inside again,this kind of molding tool accounts for 50% of total quota in profession in molding tool above. In our country,because of the late of manufacture beginning the totalitily standard of mold design was very low about the plastics of taking shape. Nowaday,The proportion of odd casement, simple casement mold was over 70percent which was still dominant. This paper introduces the main process of the injection mould designing of the union,recounts the detail as these followed:deciding of the number and the arrangement of the cavity, the detrusion components ,core-pulling outfit,and the feed system; selection of the machine for injection,the moulding boards and the standardized parts .The plastics has one side hole,so needs to design a core-pulling part from the side. As a result ,it adds the complexity of the mould.

Keywords : injection mould;core-pulling;union.

目 录

前言

1. 塑料注射模具简介

2. 国内模具的现状及发展趋势情况

3. 国外模具的发展状况

4. 模具的发展趋势

5. 本设计的研究目的

6. 研究意义

1 塑件制品的工艺性分析以及工艺性设计

1.1 塑件制品工艺性分析

1.2 材料的选择

1.3 RPVC成型性能

1.4 RPVC的主要技术指标

1.5 管接头结构工艺性能设计

2 分型面结构设计

3 型腔数量的确定

3.1 一般确定型腔数目的四种方法

3.2. 本设计中型腔的确定

4 注射机型号的确定

4.1 RPVC塑料制品成型工艺参数的确定

4.2 根据管接头注射量来初步确定注射机型号

4.3 注射机各参数的校核

5 成型零件结构设计

5.1 凹模结构设计

5.2 凹模螺纹型环尺寸计算

5.3 主型芯的尺寸计算

5.4 小型芯尺寸计算

5.5 文字镶件尺寸计算

6 型腔壁厚和底板厚度设计

6.1 型腔壁厚尺寸计算

6.2 型腔底板厚度计算

6.3 垫块厚度设计计算

6.4 固定板与支承板设计

7 侧抽芯机构设计

7.1 侧向分型与抽芯机构的分类

7.2 抽芯力的计算

8 浇注系统设计

8.1 主流道设计

8.2 冷料穴结构设计

8.3 分流道结构设计

8.4 浇口的设计

8.5 浇口套设计

9 脱模机构设计

9.1 脱模力计算

9.2 推杆的选取

9.3 保持压杆稳定性的临界条件

10导向机构设计

10.1 导向机构的基本功能

10.2 导柱遵循原则

11排气系统的设计

11.1 排溢设计

11.2 引气设计

11.3 排气系统方式

11.4 该套模具的排气方式

12 温度调节系统设计

12.1 加热系统设计

12.2 冷却系统设计

12.3 型芯的冷却

12.4 冷却系统的有关计算

13 注射模具选材

13.1 塑料模具成型零件(型腔、型芯)的选材

13.2 模板零件的选材

13.3 浇注系统零件的选材

13.4 导向零件的选材

13.5 推出机构零件的选材

13.6 其它零件

13.7 该套模具所用材料的性能比较

14 模具的工作过程

15 模具的试模与修模

15.1 注射机选定

15.2 试模用注塑料

15.3 试模工艺

15.4 试模

15.5 修模

16 模具零件加工工艺

16.1 坯料

16.2 模板的平面加工

16.3 孔及孔系的加工

16.4 成型零件的加工

17小型芯数控加工程序单

参考文献

致谢词