论文26页,16000余字,CAD图15张,模具3D

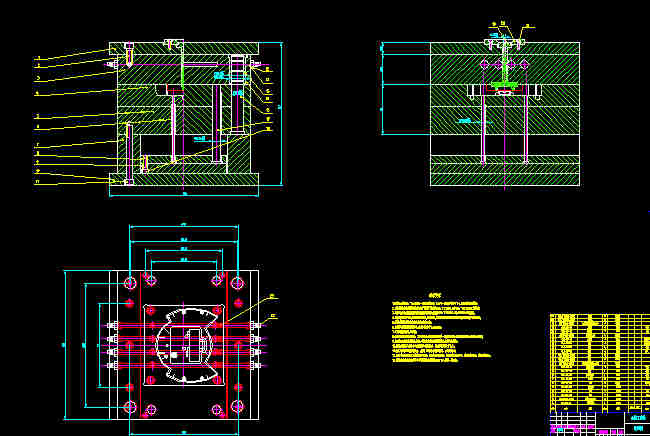

摘 要:本次研究的课题是“塑料闹钟后盖”的注塑模具设计。在结合了传统的机械设计后把PRO/E技术应用在注塑模具的设计上,在CAD系统实行了模型和注塑模具的设计。设计采用注射成形,它是成形热塑加工的主要方法,就是把塑料原料放入料筒中经过加热熔化,使之成为高黏度的流体,用柱塞或螺杆作为加压工具,使熔体通过喷嘴以较高压力注入模具的型腔中,经过冷却、凝固阶段,而后从模具中脱出,成为塑料制品。

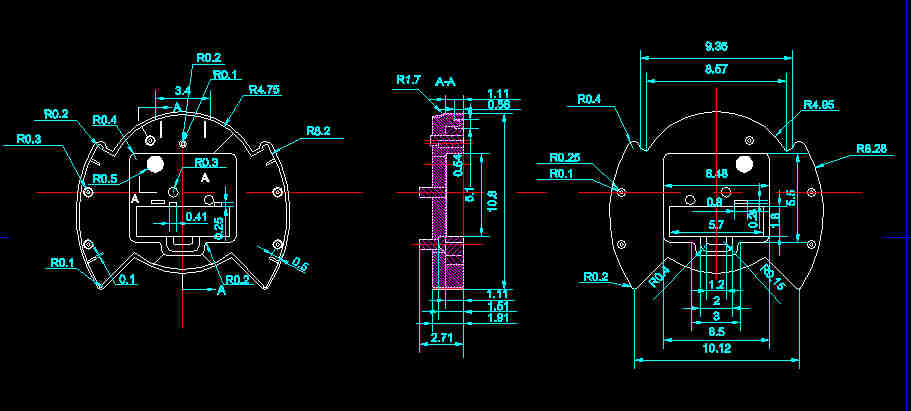

在设计过程中,首先对塑料闹钟后盖塑件进行工艺分析,了解此类型塑料的特性、用途等;在对模具的结构进行分析,根据模具的基本结构来进行对模架的选取,然后再对各种相关的工艺参数进行校核,进行对型腔和型芯等的计算。最后用PRO/E三维造型和仿真加工。

此次设计不仅使我对书本有了进一步的了解,而且让我了解到许多书本上没有的东西。理论联系实际,我在此次设计中收益很多。

关键词:型腔;PRO/E;注塑模

The injection mold design and manufacture of a back cover for Plastic Clock

Abstract: This paper is a design of injection mould, the design of this product is a “back cover for plastic clock”.It references to the traditional mechanical design, focus on the CAD/CAM application in the plastic mould design, that is to say to apply the PRO/E system in model and plastic injection mould design. The design is based on injection molding. Injection molding forming thermoplastic processing is the main method, and the raw material is melt into plastic cylinder in the heat, to make it a high viscosity of the fluid. After cooling, used as a plunger or screw compression tools, the nozzle is melt into the higher pressure in the mold cavity and the solidification stage, and then emerged from the mold, that is a plastic product.

In the design process, first of all, analyse for the plastic clock shelters of plastic parts, to understand the characteristics of this type of plastic, such as use in the mold of the structure. According to carry out the basic structure, select appropriate mould frame, then calculate for the cavity and core by checking all the relevant parameters. Finally, we can go along PRO/E 3D modeling and simulation approach processing.

The design not only makes me have a better understanding about the books, but also learn much things not founded in books. With theory contacting practice, I benefit greatly from this design.

Key word: Cavity ;Pro/E;Injection mould