摘 要

本设计在学习了普通冲压知识基础上,设计了在普通压力机上进行工作的落料冲孔复合精冲模具。分析了齿形垫片的工艺性,对几种不同工艺方案进行分析,从而确定最佳方案,介绍了垫片复合模总体结构设计和排样方案。在把普通冲裁和精密冲裁做简单比较,介绍了精密冲裁模的设计要点:由于精冲件尺寸精度高、断面垂直度良好,为使制件质量得到保证,重点设计了齿圈压板、反压板,其提供的压边力和反压力与冲裁力为材料的塑形变形提供三向不均匀压应力,使材料在精冲时处于纯剪切塑性变形状态;此外,小间隙也是精密冲裁模设计的一个要点。

关键词:齿形垫片,复合模,精冲

Abstract

The present design reports the compound fine blanking that contain blanking and punching, the basis of which is the knowledge about general blanking.The manufacturability of a gear gasket was analyzed, several different manufactures are analyzed, and the best one was determined, besides, the general structure of a compound die and the layout design for forming the par were presented. Firstly, I compare the ordinary with the fine blanking simply, then, the key points in designing the fine blanking die were introduced. as the parts obtained from the fine blanking have more precise size, good degree of vertical cross-section, in order to get part with high quality, I focus on the design of the ring gear plate and anti-plate, which provide the forces make the materials under the three non-uniform compressive stress, as a result, the material is always in a pure shear plastic deformation state during the processing of fine blanking; in addition, the smaller gap is also a key point.

Key words: Gear gasket piece, Compound die, Fine blanking

目 录

前 言 1

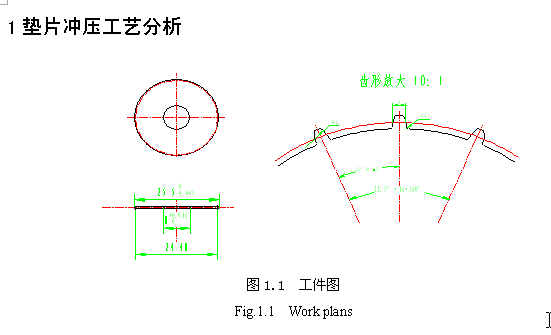

1.垫片冲压工艺分析 3

1.1产品结构形状分析 3

1.2产品尺寸精度、粗糙度、断面质量分析 3

2.工艺方案确定 4

2.1冲压工序 4

2.2.工艺方案分析 4

2.3.工艺方案选择 6

3.垫片精冲模结构的确定 8

3.1.模具形式 8

3.2.定位装置 8

3.3.卸料装置 8

3.4.导向零件 8

3.5.模架 8

3.6.模具总体结构设计 9

4.垫片冲压工艺计算 10

4.1确定排样方式 10

4.2.排样相关量的计算 10

4.3.排样图 11

5.冲压力及压力中心计算 12

5.1.冲裁力 12

5.2齿圈压边力 12

5.3.反压力 12

5.4. 总压力 13

5.5.卸料力和顶件力 13

5.6.计算模具压力中心 13

6.冲压设备的选择 14

6.1.冲压设备类型的选择 14

6.2.冲压设备规格的选择 14

6.3.冲压设备的确定 15

7.主要零部件的设计 16

7.1.V形压边圈的设计计算 16

7.2.凸凹模的设计计算 17

7.2.1.凸凹模间隙 17

7.2.2. 冲裁凸、凹模刃口尺寸计算原则 18

7.2.3.凸、凹模刃口尺寸的计算方法 18

7.2.4凸、凹模其他尺寸的确定及模具固定方式 19

7.3.反压板的设计 23

7.4.定位零件的设计 24

7.5.导向零件的设计 24

7.6.碟形弹簧的确定 25

7.7.紧固零部件的设计 27

7.8.固定与支撑零件的设计 27

7.9.模架的选择 29

8.排气与润滑 30

8.1排气 30

8.2.润滑 30

9.精冲模具材料 31

10.模具的加工特点及装配工艺性 32

10.1.模具的加工特点 32

10.2模具装配工艺性 32

10.3其他零件的装配 32

结 论 34

致 谢 35

参考文献 36